Motor Encoder

Motor Encoder Specification

- Features

- Sturdy construction, High accuracy, Durable finish

- Product Type

- Motor Encoder

- Color

- Black & Silver

Motor Encoder Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- South India

About Motor Encoder

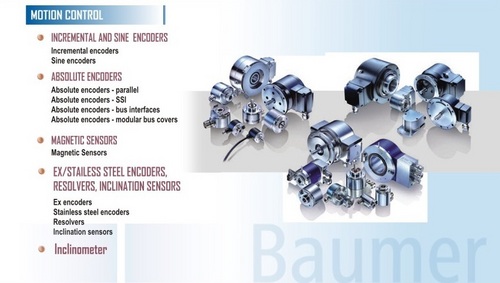

Encoders

We offer a wide range of Encoder that are known for their excellent performance and longer functioning life. These Encoder are available in diverse designs and modals to suit the varied requirements of our clients.

Exceptional Precision and Durability

Engineered for high-accuracy requirements, this rotary optical encoder ensures reliable performance in precision motion control systems. Its sturdy metal construction offers excellent resistance to mechanical stress, while the tough finish guarantees longevity, even under rigorous operating conditions.

Versatile Connectivity and Mounting

Choose between radial or axial cable entries and benefit from standard round flange mounting for simplified integration. The encoder accommodates various connection needs with M12 and customizable connector options, enabling seamless adaptation to a wide range of industrial setups.

Optimal Performance Across Environments

With an operational temperature range from -20 C to +85 C, this optical encoder delivers consistent, precise feedback in both indoor and outdoor conditions. Its advanced sensing technology makes it an ideal choice for motion control tasks in diverse industrial sectors throughout India.

FAQs of Motor Encoder:

Q: How does this rotary optical encoder enhance precision in motion control applications?

A: The encoder uses advanced optical sensing technology to deliver high-resolution feedback, ensuring precise position and speed measurement. This level of accuracy is vital for complex motion control tasks such as robotics, CNC machinery, and automated assembly systems.Q: What types of output signals are available with this encoder, and how do they benefit different applications?

A: Depending on the model, the encoder provides either incremental or absolute output signals. Incremental outputs are ideal for tracking relative differences, while absolute outputs supply exact position databoth are essential for versatile automation needs in industry.Q: When should I choose radial versus axial cable entry for installation?

A: Radial cable entry is generally preferred when space is limited around the installation area, while axial cable entry facilitates straight routing in line with the encoder shaft. The choice depends on the equipment design and available mounting space.Q: Where can this encoder be installed, considering its durability and temperature range?

A: Designed for rugged environments within the temperature range of -20 C to +85 C, this encoder is suitable for installation in various settings, including manufacturing plants, outdoor machinery, and precision laboratory equipment across India.Q: What is the installation process for the standard round flange mounting?

A: The encoder comes with a standard round flange, allowing for secure attachment to compatible motor housings or machinery frames. Installation typically involves bolting the flange onto the equipment and connecting the cable to the M12 or customizable connector provided.Q: How does the robust metal construction benefit long-term industrial usage?

A: The metal housing offers excellent protection against shocks, vibration, and harsh industrial environments. Combined with a durable finish, this ensures extended operational life and reduced maintenance costs.Q: What support is available for custom connector requirements in India?

A: As a distributor and supplier in India, we offer customizable connector solutions. Customers can specify their preferred connector type during ordering, and our team will ensure seamless integration with existing industrial setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Encoder Category

Incremental Encoders

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black/Silver

Product Type : Other, Incremental Encoder

Noise Level : Low

Sealed Type : Other, Sealed (IP65)

Pneumatic Double Acting Square Cylinder ( ISO STANDARD )

Color : Metallic silver

Product Type : Pneumatic Double Acting Square Cylinder, Other

Noise Level : Quiet operation

Sealed Type : Sealed design to prevent leaks, Other

Absolute Encoders

Price 500-100000 / Piece

Minimum Order Quantity : 1 Piece

Color : Silver Black

Product Type : Other, Absolute Encoder

Noise Level : <60 dB

Sealed Type : Other, IP65 Sealed

Motion Encoder

Price 500-100000 / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Product Type : Other, Motion Encoder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry