Motion Encoder

Motion Encoder Specification

- Features

- High precision, Compact design

- Product Type

- Motion Encoder

- Color

- Black

- Mounting Type

- Panel Mount

- Resolution

- Incremental (as shown in image)

- Shaft Type

- Hollow Shaft

- Output Signal

- TTL/HTL Compatible

- Operating Voltage

- 524 VDC

- Cable Length

- Approx. 2 meters

- Encoder Type

- Rotary Encoder

- Material

- Metal and ABS Plastic Body

- Operating Temperature

- -10C to +70C

- Application

- Industrial Automation, Robotics, Motion Feedback

Motion Encoder Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- South India

About Motion Encoder

With the help of our dexterous professionals, we are engaged in manufacturing, exporting and supplying quality range of Motion Encoder. This encoder is used to various industries as a versatile device for encoding electrical and mechanical data for further devices operations. Offered encoder is manufactured by inculcating advanced technology and supreme grade metals & allied raw materials under the stern guidance of our team of technical experts. Further, the Motion Encoder is checked on various quality measures by our team of controllers. Clients can avail this encoder from us in different specifications at affordable prices.

Features:

-

Easy installation

-

Durable finish standards

-

Light weight

-

Longer service life

High Precision Motion Feedback

Designed for accurate and consistent motion data, the encoder supports high-resolution feedback in automation and robotic systems. Its incremental output makes it suitable for detecting changes in position, direction, and speed, enabling superior control for precise applications.

Robust Build for Industrial Settings

Constructed using metal and ABS plastic, the encoder withstands harsh industrial environments. The compact, hollow shaft format streamlines installation, while panel mounting provides secure and reliable integration into automation equipment.

Versatile Signal Compatibility

The TTL/HTL output options ensure seamless interfacing with diverse control systems and hardware, broadening the encoders utility across various industrial and robotics applications. The extended operating voltage enhances compatibility with different power sources.

FAQs of Motion Encoder:

Q: How does the incremental rotary encoder enhance motion feedback accuracy in industrial automation?

A: The incremental rotary encoder provides high-resolution feedback that allows for precise measurement of motion variables such as speed, position, and direction. This accuracy is vital for optimal performance in automation and robotics, improving control and productivity.Q: What are the key benefits of using a hollow shaft encoder with a panel mount design?

A: A hollow shaft construction simplifies shaft coupling, making installation easier and reducing mechanical stress. Panel mount ensures secure attachment, resulting in reliable performance in demanding industrial environments.Q: When is a TTL/HTL output signal preferred for motion encoders?

A: TTL/HTL compatible signals are favored when the encoder needs to interface with PLCs, controllers, or drive systems commonly found in automation and robotics, offering versatility and stable operation across different setups.Q: Where can this motion encoder be effectively installed?

A: The encoder can be mounted on panels in automated machinery, robotics, conveyor systems, and other industrial applications requiring precise motion detection, thanks to its compact size and robust construction.Q: What is the process for integrating the rotary encoder into existing automation equipment?

A: Integration involves mounting the encoder on a compatible panel using the hollow shaft design, connecting the approximately 2-meter cable to the control hardware, and configuring the TTL/HTL signal output according to system requirements.Q: How does the wide operating voltage and temperature range benefit industrial users?

A: The wide voltage range (524 VDC) and temperature tolerance (-10C to +70C) allow the encoder to function reliably across diverse environments, minimizing downtime and supporting a variety of power configurations in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

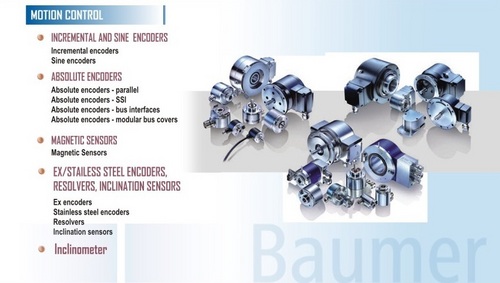

More Products in Industrial Encoder Category

Incremental Encoders

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Incremental Encoder

Color : Black/Silver

Features : High Resolution, Durable Build, Compact Design, Easy Installation

Dimension (L*W*H) : Approx. 50mm Diameter (varies by model)

Pneumatic Double Acting Square Cylinder ( ISO STANDARD )

Product Type : Pneumatic Double Acting Square Cylinder, Other

Color : Metallic silver

Features : Double Acting ISO Standardcompliant durable construction

Dimension (L*W*H) : Varies depending on model; conforms to ISO standard

Absolute Encoders

Price 500-100000 / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Absolute Encoder

Color : Silver Black

Dimension (L*W*H) : 50 mm x 56 mm x 32 mm

Motor Encoder

Price 500-100000 / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Motor Encoder

Color : Black & Silver

Features : Sturdy construction, High accuracy, Durable finish

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry