Incremental Encoders

Price 500-100000 INR/ Piece

Incremental Encoders Specification

- Efficacy

- High Reliability

- Current Type

- DC

- Bearing Type

- Ball Bearing

- Sealed Type

- Sealed (IP65)

- Features

- High Resolution, Durable Build, Compact Design, Easy Installation

- Noise Level

- Low

- Product Type

- Incremental Encoder

- Protect Feature

- IP65 Sealed Housing

- Speed

- 6000 RPM Max

- Color

- Black/Silver

- Dimension (L*W*H)

- Approx. 50mm Diameter (varies by model)

- Shaft Diameter

- 6mm, 8mm, Others (based on model)

- IP Rating

- IP65

Incremental Encoders Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia, North America

- Main Domestic Market

- South India

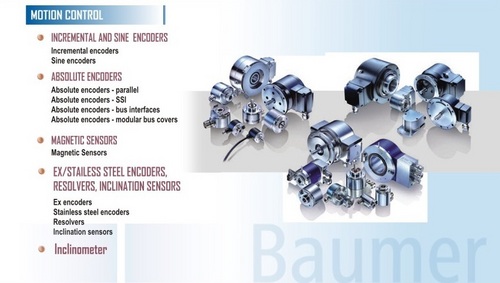

About Incremental Encoders

We are an unparalleled name in manufacturing, exporting and supplying premium quality range of Incremental Encoders. These encoders are suitable for replicating data of applications where it requires measurement of speed, travel, length and direction of rotation. Manufactured using supreme grade basic components, these encoders are available in different specifications as per the application requirements of customers. Our provided encoders are quality approved on various measures to ensure their flawless performance at our clients' end. Clients can avail this Incremental Encoders at market leading price range.

Features:

-

Longer service life

-

Less power consumption

-

Rugged construction

-

Excellent performance

Specifications:

-

Types encoders : optical technology / magnetic technology / integral bearings / bearing less / heavy duty.

-

Housing : 24mm to 227mm

-

Shaft : hallow through / hallow end

-

Solid shaft dia : 4mm to 12mm

-

Hallow shaft : 4mm to 65mm

-

Operating sped : 1000 RPM to 12000 RPM

-

Resolutions ( steps / turn) : 1PPR to 36000 PPR and above upto 1.3 million PPR

-

Output circuit : Square waves / sine waves / TTL / RS 422 / HTL / HTL / PUSH - PULL / HTL : POWERLINE DRIVER

-

Connection : cable type / connected type / terminal box / plug in terminal

-

No of channels : 6 Channels

-

Directions : clock rotation / anti clock / PPR output

-

Cable connector : axial / radial

-

Mountings : synchro flange / synchro mounting / clamping flange

-

Supply Volt : 10to 30 VDC

-

Temprature : 22 to 85 degree celcius for standard and high temprature also available

-

Protection : IP65

IP65 Sealed Housing for Enhanced Protection

Engineered with a sealed IP65-rated enclosure, these incremental encoders withstand dust, water, and debris. The sealed design makes them ideal for harsh industrial environments, minimizing maintenance and ensuring the internal mechanisms remain unaffected by external contaminants. This robust protection translates to a longer service life and reduced downtime.

High Reliability and Performance

Operating with ball bearings and supporting speeds up to 6000 RPM, these encoders deliver stable, high-resolution feedback for critical motion-control tasks. Their durable build paired with low noise output makes them suitable for diverse automation setups, ensuring accuracy and reliability even in demanding operational scenarios.

Versatile and Easy to Integrate

With compact dimensions and flexibility in shaft diameters (6mm, 8mm, and more), these encoders optimally fit assorted installation requirements. Their straightforward installation process allows fast and secure mounting, minimizing setup time. This versatility makes them an excellent choice for OEMs, distributors, and system integrators in India.

FAQs of Incremental Encoders:

Q: How does an IP65-rated sealed housing benefit incremental encoders in industrial environments?

A: An IP65-sealed housing protects incremental encoders from dust, water sprays, and other contaminants found in industrial environments. This elevated level of protection increases their durability and reliability, minimizing failures or performance issues caused by harsh conditions.Q: What makes these incremental encoders highly reliable for automation applications?

A: These encoders are engineered with high-resolution output, robust ball bearings, low noise, and a sealed IP65 housing. Together, these features ensure accurate, consistent performance with minimal maintenance, which is essential for automated systems demanding uptime and precision.Q: When should I choose an incremental encoder with a sealed IP65 housing?

A: You should select an incremental encoder with an IP65-sealed housing when your application involves exposure to dust, moisture, or challenging industrial conditions that could impair unprotected devices. This ensures longevity and consistent operation.Q: Where can these IP65 incremental encoders be installed?

A: Their compact, robust build makes them suitable for installation in a wide array of machinery, automation equipment, and conveyors. They are most commonly found in industrial settings, manufacturing plants, and any application where reliable position feedback under tough conditions is necessary.Q: What is the installation process for these incremental encoders?

A: The encoders are designed for straightforward installation, with adaptable shaft diameters (6mm, 8mm, and others) and a compact 50mm diameter body. This allows easy integration into both new and existing systems without complex modifications.Q: How do users benefit from the high resolution and low noise features of these encoders?

A: High-resolution feedback enables precise motion control, leading to better system accuracy and efficiency. The low noise level ensures quiet operation, which is particularly advantageous in settings where noise pollution needs to be minimized.Q: What are the supply and distribution options for these encoders in India?

A: These IP65 incremental encoders are available through authorized distributors and suppliers across India, ensuring reliable support and prompt delivery to local customers in various sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Encoder Category

Pneumatic Double Acting Square Cylinder ( ISO STANDARD )

Color : Metallic silver

Product Type : Pneumatic Double Acting Square Cylinder, Other

Mounting Type : Adjustable mounting options depending on design

Features : Double Acting ISO Standardcompliant durable construction

Absolute Encoders

Price 500-100000 / Piece

Minimum Order Quantity : 1 Piece

Color : Silver Black

Product Type : Other, Absolute Encoder

Mounting Type : Flange Mounting

Motion Encoder

Price 500-100000 / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Product Type : Other, Motion Encoder

Mounting Type : Panel Mount

Features : High precision, Compact design

Motor Encoder

Price 500-100000 / Piece

Minimum Order Quantity : 1 Piece

Color : Black & Silver

Product Type : Other, Motor Encoder

Features : Sturdy construction, High accuracy, Durable finish

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry