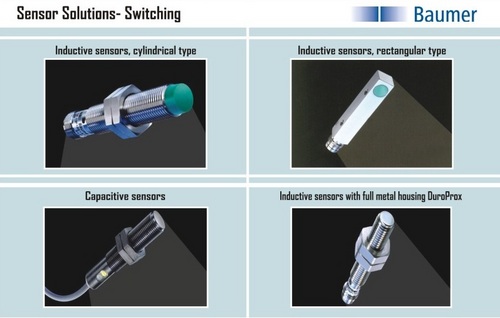

Inductive Sensors

Price 5-100000 INR/ Piece

Inductive Sensors Specification

- Sensor Type

- Proximity Sensor

- Sensitivity

- Adjustable (select models)

- Power Consumption

- 10 mA (no load)

- Mounting Type

- Threaded/Cylindrical mounting

- Response Time

- <1 ms

- Cable Length

- 2 meters (standard)

- IP Rating

- IP67

- Signal Type

- Digital

- Interface

- Cable

- Application

- Automation equipment, Conveyors, Robotics, Industrial machinery

- Wireless

- No

- Product Type

- Inductive Sensor

- Material

- Stainless Steel

- Usage

- Position sensing, Counting, Speed measurement

- Accuracy

- 0.01 mm

- Resolution

- 0.01 mm

- Weight

- Approx. 50g

Inductive Sensors Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- South India

About Inductive Sensors

Our enterprise has gained immense recognition in the industry by manufacturing, exporting and supplying an excellent quality assortment of Inductive Sensor. This sensor is used for detecting the presence of excessive metallic substance in the material, also it is governed by the principle of Damped Oscillator. The offered sensor is manufactured by our dexterous team of experts by utilizing fine grade raw materials with the help of modern techniques in the well equipped manufacturing unit. We provide this Inductive Sensor in different specifications according to the client's exact need.

Features:

-

Compact design

-

Rust and Water proof

-

Feasible in ant temperature

-

Strong construction

Inductive Sensors

Model of Sensors - Cylindrical / Rectangular / FullMetal Housing / Hygenic / Washdown

Sensing Dia - 0.8 mm to 30mm

Type Of Sensors - Metal Sensing / Non Metal Sensing / Magnetic Sensing

Housing of Seoles - Flush Type & Non Flush Type

Output - PNP & NPN / 4 - 20 mamps / 10V

Supply Volt - 10 to 30 VDC

Switching Frequency - 15hz to 3khz

Enclosure - Class IP 67/IP69K

Exceptional Accuracy and Fast Response

Engineered for precise measurement tasks, these inductive proximity sensors achieve an impressive accuracy of 0.01 mm and a resolution down to 0.01 mm. Their rapid response time of under 1 ms ensures they capture even the quickest movements, making them highly effective for speed measurement and high-speed automation processes.

Robust Construction for Industrial Environments

Encased in durable stainless steel and boasting an IP67 protection rating, these sensors withstand dust, moisture, and mechanical stress. The rugged build makes them a reliable choice for automation equipment, conveyors, robotics, and various types of industrial machinery.

Simple Integration and Flexible Usage

Installation is straightforward, thanks to threaded or cylindrical mounting options and a standard 2-meter cable interface. Select models offer adjustable sensitivity, allowing for tailored solutions in diverse applications across the factory floor.

FAQs of Inductive Sensors:

Q: How do these stainless steel inductive sensors function in industrial automation?

A: These sensors utilize electromagnetic fields to detect metallic targets without physical contact, making them ideal for automation tasks such as position sensing, counting items, and measuring the speed of moving machinery components.Q: What applications are best suited for this proximity sensor model?

A: Their robust build and accurate performance make them perfect for automation equipment, conveyor systems, industrial machinery, and robotic arms where precise position and speed monitoring is essential.Q: When should the adjustable sensitivity feature be used?

A: Adjustable sensitivity (available on select models) is particularly beneficial when dealing with varying object sizes or materials, allowing the sensor to be fine-tuned for optimal detection without false triggers or missed targets.Q: Where can these sensors be installed within an industrial setting?

A: Thanks to their IP67 rating and sturdy construction, these sensors can be mounted in environments with exposure to dust, oil, or water, including production lines, packaging machines, and outdoor automation equipment.Q: What is the process for mounting these sensors?

A: Installation is facilitated by the threaded or cylindrical mounts, which fit standard industrial brackets. The 2-meter cable provides flexibility for routing to control panels or PLCs for signal integration.Q: How can users benefit from the sensors accuracy and fast response time?

A: The high accuracy and quick response ensure that even minimal or rapid movements are detected reliably, reducing errors, improving productivity, and enhancing the precision of automated processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

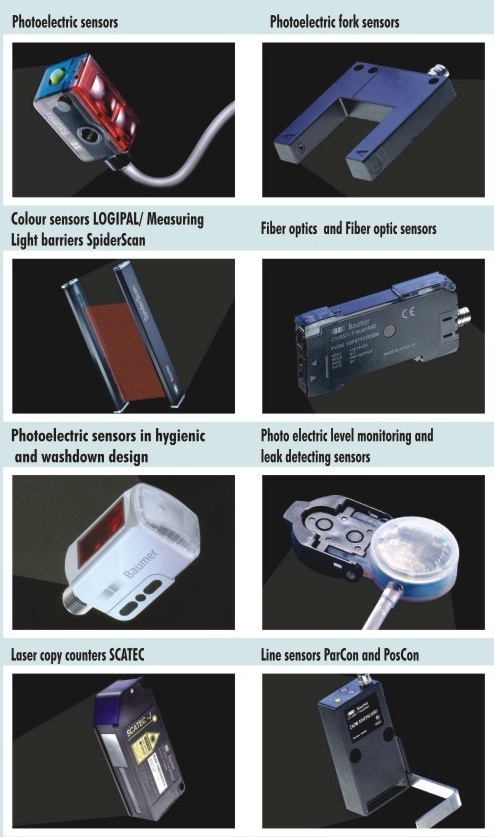

More Products in Electric Sensors Category

Photoselectric Sensors

Price 5-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : High

Usage : Industrial Automation

Product Type : Photoelectric Sensor

Application : Detecting, Counting, Positioning

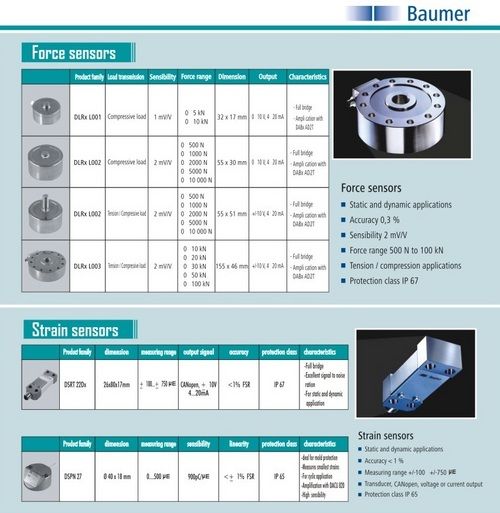

Force Sensors

Price 5-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : 0.5% F.S.

Usage : Industrial force measurement applications

Product Type : Force Sensor

Application : Automation, Robotics, Machine Testing

Capacitive Sensors

Price 5-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : 2% F.S.

Usage : Object detection, level monitoring

Product Type : Capacitive Sensor

Application : Automation, Packaging, Food, Pharma, Plastic, Agriculture Industries

Ultrasonic Sensors

Minimum Order Quantity : 1 Piece

Accuracy : 99.9 %

Usage : Electrical Instruments

Product Type : Ultrasonic Sensors

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry