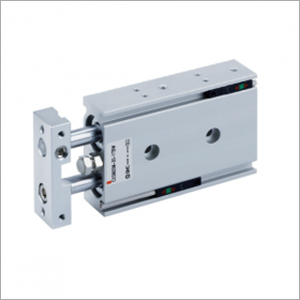

Rotary Clamp Cylinder

Price 500-100000 INR/ Piece

Rotary Clamp Cylinder Specification

- Capacity

- Up to 30 kg clamping force

- Wall Thickness

- 6 mm

- Pressure

- 0.15 - 1 MPa

- Temperature

- -10C to +70C

- Material

- Aluminum Alloy

- Structure

- Rotary Clamp

- Power

- Pneumatic

- Dimensions

- Bore: 32 mm, Total Length: 175 mm

- Max. Stroke

- 50 mm

- Shaft Diameter

- 15 mm

- Seals Type

- NBR (Nitrile Rubber) Seals

- Rod

- Single Rod

- Weight

- 1.8 kg

Rotary Clamp Cylinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Week

About Rotary Clamp Cylinder

Exceptional Versatility & Mounting Options

The rotary clamp cylinder is designed to adapt to a wide variety of installation requirements. With both foot and flange mounting options, users can integrate it seamlessly into existing machinery or custom-built setups. The adjustable rotary angle (90/180) offers additional flexibility for diverse industrial automation tasks.

Durability and High Performance

Thanks to its anodized aluminum body, replaceable steel arm, and robust NBR seals, this rotary clamp cylinder is built for longevity. It serves reliably in harsh environments, resisting corrosion and maintaining a cycle life of over 10 million cycles. Its integrated rubber bumpers absorb shock for quieter operation and reduced wear.

Precision Clamping for Industrial Automation

With 0.1 mm repeatability and up to 30 kg clamping force, this cylinder provides precise, repeatable performance essential in welding fixtures, jigs, and automated systems. It operates efficiently with filtered, lubricated, or non-lubricated air, ensuring optimal results in a range of applications common in industrial manufacturing.

FAQs of Rotary Clamp Cylinder:

Q: How is the rotary angle adjusted on this clamp cylinder?

A: The rotary angle of this clamp cylinder can be conveniently set to either 90 or 180, allowing users to select the most suitable position for their clamping application. Adjustment is typically made by altering the stop positions or limit settings according to the installation guide.Q: What benefits does the anodized aluminum alloy provide for industrial use?

A: The anodized aluminum finish ensures enhanced corrosion resistance and surface durability, making the cylinder suitable for demanding industrial environments where exposure to moisture or chemicals may occur.Q: When should the clamp arm be replaced, and is it user-serviceable?

A: The steel clamp arm is designed for easy replacement if it shows signs of wear or damage after extensive use. Replacement is straightforward and can be completed by maintenance personnel without the need for specialized tools.Q: Where can this rotary clamp cylinder be installed in an automation system?

A: Thanks to its foot and flange mounting options, the cylinder can be installed on various fixtures, frames, or system bases involved in welding, jig fabrication, or automated clamping processes throughout industrial facilities.Q: What is the recommended operating medium, and is lubrication mandatory?

A: The cylinder is engineered for use with filtered air and supports both lubricated and non-lubricated air operation, ensuring flexibility in pneumatic system design and maintenance routines.Q: How does the cylinder ensure reliable and repeatable clamping?

A: With a repeatability of 0.1 mm and integrated rubber bumpers at both stroke ends, the cylinder guarantees consistent and precise clamping over millions of cycles, minimizing positional variation and tool wear.Q: What is the maximum piston speed and operating pressure range for this product?

A: The cylinder operates efficiently at piston speeds ranging from 50 to 500 mm/s, and at a working pressure between 0.15 and 1 MPa, allowing adaptation to diverse industrial requirements while maintaining safety and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Cylinders Category

3 Position Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Anodized aluminium cylinder, steel shaft

Weight : Varies by stroke and bore size (consult manufacturer)

Capacity : Multiple position actuation (3positions)

Max. Stroke : Up to 500 mm (depending on bore)

Precision Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, High tensile steel/EN8, EN9

Weight : Approx. 510 kg (varies by model)

Capacity : Up to 1000 mm stroke

Max. Stroke : 1000 mm

Dual Rod Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Aluminium alloy body, chromeplated steel rod

Weight : 3.2 kg

Capacity : Variable, dependent on bore size and stroke

Max. Stroke : 500 mm

Valve Mounted Guide Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Aluminum alloy body

Weight : 2.5 kg

Capacity : Single/Double acting

Max. Stroke : 100 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry