Pipe Line Valve

Price 500-100000 INR/ Piece

Pipe Line Valve Specification

- Operating Voltage

- Manual Operation (No Voltage)

- End Connection

- Flanged

- Working Presssure

- 16 Bar

- Material

- Cast Iron

- Valve Structure

- Flanged

- Processing Type

- Precision Casting

- Pressure

- 16 Bar

- Dimension (L*W*H)

- 10 x 7 x 6

- Port Size

- 100 mm

- Connection Type

- Bolted Flange

- Application

- Industrial Pipeline

- Media

- Water, Oil, Gas

- Working Temperature

- Up to 120C

- Weight

- 17 kg

- Color

- Blue

Pipe Line Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- South India

About Pipe Line Valve

Leveraging on our vast industry experience and knowledge, we have emerged as one of the notable manufacturer, exporter and supplier of premium quality Pipe Line Valve. The offered line valve is manufactured using premium quality raw materials and advanced technology under the supervision of our experts. Provided line valve is widely used in various industries as a stopper, connector and various applications to control and maintain the flow of liquid in the transmission pipes. Our valuable clients can avail this Pipe Line Valve from us at reasonable prices.

Features:

-

Excellent durability

-

Anti-corrosive

-

Long operational life

-

Flawless finish

Specifications:

GUN METAL VALVES

-

GATE VALVES, GLOBE VALVE, SAFETY VALVE, CHECK VALVE,

-

STEAM TRAP, UNION BONNET STEAM VALVE, FOOT VALVE

-

SIZE : 1/2" TO 3"

-

CONNECTION ; Threaded, Flanged,

-

Pressure : 0 to 25 kg/cm2

-

MAKE : PILOT, AURUM, ELEMS

GATE VALVE

-

BS 1414/BS 5352/API 600/API 602/

-

API 6 D/A SME B 16 34 / ADI 598

-

Stainless Steel (Bar Stock)

-

Rating : 150#/300#

-

Size : 8mm to 100mm

-

Forged Carbon Steel / S.Steel

-

Rating : 150#/300#/800#/1500#

-

Size : 25mm to 600mm

-

Cast Carbon Steel/S.Steel/Alloy Steel

-

Rating : 150#/300#/800#/900#

-

Size : 25mm to 600mm

-

Cast Iron

-

Rating : 125# /150#

-

Size : 25mm to 600mm

-

Forged Iron Cast Iron

-

Pressure/Tem

-

Rating ANSI B 16.34/API 6D ANSI B 16.34

-

Design (Std) API 602 / BS 5352 API 600 / API 6D

-

Test (Std) API 598 / BS 6755 API 598 / API 6D

NON RETURN VALVE

BS 6755/BS 1868/ ASME B 16.34 API 6D

-

Stainless Steel (Bar Stock)

-

Rating : 150#/300#

-

Size : 8mm to 100mm

-

Forged Carbon Steel / S.Steel

-

Rating : 150#/300#/800#/1500#

-

Size : 15mm to 50mm

-

Cast Carbon Steel/S.Steel/Alloy Steel

-

Rating : 150#/300#/800#/900#

-

Size : 25mm to 600mm

-

Cast Iron

-

Rating : 125# /150#

-

Size : 25mm to 600mm

-

Forged Iron Cast Range

-

Design BS 5352 BS 1868/API 6D

-

Test BS 6755 BS 6755 / API 6D

DIN GLOBE VALVE

-

BS 6755/BS 1873/ ASME B 16.34/ DIN 3356

-

Cast Carbon Steel/S.Steel

-

Rating : PN 40/ PN 64

-

Size : 25mm to 300mm

-

Design Std : BS 1873 / DIN 3356

-

Test : BS 6755

-

Cast Iron

-

Rating : PN 10/PN 16

-

Size : 15mm to 250mm

BUTTERFLY VALVES

-

Materials : CI, SS, PP, Dairy Polished SS

-

Type : Hand Lever, Gear Operated

-

Wheel type

-

Seating : PTFE, EPDM, Nitrile

-

Disc : CI , SS, PP

-

Size : 1 to 12

WAFER TYPE CHECK VALVE

-

Carbon steel

-

Size : 25mm to 600mm

-

Ends : Wafer Type

-

Stainless Steel

-

Size : 25mm to 600mm

-

Ends : Wafer Type

FORGED BALL VALVE

-

Forged Carbon Steel / Stainless Steel

-

Design : 3 PC (BS 5351 / API 609)

-

Ends : Screwed/Socket Weld

-

Size : 15mm to 50mm

-

Test : BS 6755/API 607 / API 6D

DIAPHARGM VALVE

-

Cast Iron / SS 304

-

Lining : Natural Rubber / Ebonite

-

Neoprene / Nitrile

-

Size : 15mm to 200mm

-

Ends : Flanged / Triclover

High-Quality Materials and Construction

Engineered with a cast iron body, ductile iron disc, and stainless steel stem, this valve offers exceptional strength and longevity. The bronze seat and soft sealing further enhance operational reliability, especially in applications demanding precise shutoff and minimal leakage. Epoxy powder coating adds significant resistance against corrosion, making it a solid choice for challenging conditions.

Flexible Application and Easy Installation

Supporting both horizontal and vertical mounting, this valve is adaptable to a wide range of piping configurations in various industrial settings. The flanged and bolted connection ensures a secure fit, while manual handwheel operation makes the valve straightforward to use. With a port size of 100 mm and robust dimensions, it can handle significant flow rates efficiently.

FAQs of Pipe Line Valve:

Q: How does the valve ensure high corrosion resistance in tough environments?

A: The valve is coated with an epoxy powder, which provides a robust barrier against corrosion. Combined with the use of stainless steel for the stem and ductile iron for the disc, this coating allows the valve to maintain performance and resist damage in water, oil, and gas industrial settings.Q: What is the benefit of a soft-seated, Class A sealing valve?

A: A soft-seated, Class A sealing ensures minimal leakage, providing a tight shutoff that is essential where precise fluid control is required. This contributes to safer operation and reduced product loss in pipelines, making it suitable for critical applications.Q: When should this valve be used in an industrial pipeline system?

A: This valve is most effective for water, oil, or gas pipelines that require reliable shutoff and control at pressures up to 16 Bar and temperatures up to 120C. Its long service life and robust construction make it ideal for continuous or demanding operations in industrial facilities.Q: Where can the valve be installed within a piping system?

A: It is designed for versatility, allowing installation in both horizontal and vertical orientations. The flanged, bolted connection makes it compatible with standard pipeline setups throughout industrial facilities.Q: What is the process for operating this valve and does it require electrical power?

A: Operation is manual, using a handwheelno electrical power or operating voltage is required. Simply turning the handwheel opens or closes the valve, providing precise control over the flow of fluids.Q: How does precision casting contribute to the valves performance?

A: Precision casting ensures a uniform and dense structure, reducing the risk of flaws or leaks. This production method yields a highly durable valve body, promoting long-term reliability even under pressurized conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

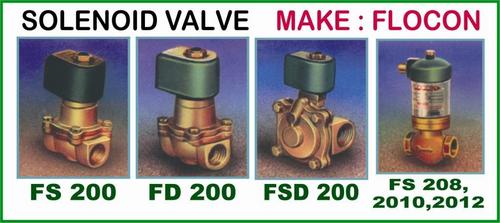

More Products in Solenoid Valves Category

Pressure Relief 3 Port Valve

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Working Temperature : Up to 80C

Port Size : 1/2 inch NPT

Way Type : ThreeWay

Application : Hydraulic and Pneumatic Systems

Residual Relief 3 Port Valve

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Working Temperature : 10C to 120C

Port Size : 1/2 inch BSP

Way Type : Other, 3 Way

Application : Industrial Process Control

4 Way Solenoid Valve

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Working Temperature : Up to 80C

Port Size : 1/4 inch BSP

Way Type : Other, 4 Way

Application : Control of air, gas, liquid and vacuum in automation systems

Electro Pneumatic Valve

Working Temperature : 10C to 60C

Port Size : 1/4 inch

Way Type : Other, 2Way

Application : Industrial Automation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry