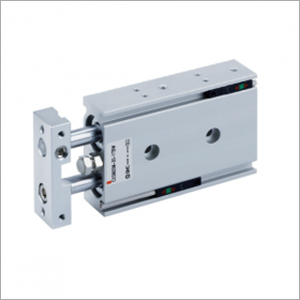

Magnetically Coupled Rodless Cylinder

Price 500-100000 INR/ Piece

Magnetically Coupled Rodless Cylinder Specification

- Wall Thickness

- Standard, up to 2.5 mm

- Capacity

- Varies by model, up to 50 kg load-carrying

- Pressure

- 0.15~0.7 MPa

- Temperature

- -10C to +60C

- Material

- Anodized Aluminum body

- Structure

- Magnetically coupled, rodless cylinder

- Power

- Pneumatic

- Dimensions

- Available bore sizes: 16 mm, 25 mm, 32 mm, 40 mm

- Max. Stroke

- Up to 2000 mm

- Shaft Diameter

- Standard (varies by bore size, e.g., 25 mm)

- Seals Type

- Polyurethane/NBR seals

- Rod

- Rodless - Magnetically Coupled

- Weight

- 2.5 kg (approx. for standard size)

- Position Sensor Compatibility

- Integrated slots for magnetic sensors

- Repeatability

- ±0.1 mm

- Mounting

- Flexible mounting options, includes brackets and sensor slots

- Application

- Material handling, packaging, pick-and-place automation systems

- Protection Class

- IP67 Carriage

- Port Size

- M5 or 1/8'' BSP (depends on bore size)

- Leakage Resistance

- Zero external leakage design

- Coupling Type

- Magnetic coupling, non-contact between piston and carriage

- Medium

- Filtered, lubricated or non-lubricated compressed air

- Speed Range

- 50 mm/s to 1000 mm/s

- Cushion Type

- Adjustable air cushion at both ends

Magnetically Coupled Rodless Cylinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- South India

About Magnetically Coupled Rodless Cylinder

Distinctive Features & Competitive Advantage

Our Magnetically Coupled Rodless Cylinder stands out with its distinguished zero leakage design, adjustable air cushion, and high repeatability. Its polished anodized aluminum construct offers durability, while flexible mounting and built-in sensor slots enhance adaptability in packaging and automation. Utilise this crowning pneumatic solution for material handling, pick-and-place, and other precision-driven processessecuring higher operational efficiency and reliably consistent results in your systems.

Sample Availability & Export Credentials

Supply your project demands with easesamples of the Magnetically Coupled Rodless Cylinder are available for evaluation and performance estimation. Major export markets include Asia and Europe, and every unit is dispatched swiftly from verified suppliers to ensure timely delivery. The product is certified to meet relevant industrial standards, affirming quality and reliability for discerning clients who seek international-grade pneumatic solutions.

FAQs of Magnetically Coupled Rodless Cylinder:

Q: How does the magnetic coupling in the rodless cylinder benefit usage?

A: The magnetic coupling ensures non-contact operation between the piston and carriage, preventing external leakage and enhancing durability, making it ideal for clean and maintenance-friendly industrial environments.Q: What is the process for mounting the Magnetically Coupled Rodless Cylinder?

A: The cylinder features flexible mounting options, including brackets and integrated sensor slots, allowing straightforward installation and adaptation to different systems.Q: Where can this rodless cylinder be effectively used?

A: This product is well-suited for material handling, packaging, and pick-and-place automation systems, thanks to its reliability, precision (0.1 mm repeatability), and load-carrying capacity of up to 50 kg.Q: What advantages does the adjustable air cushion offer?

A: The adjustable air cushion at both ends helps to absorb shock, prolongs the cylinders service life, and enables smooth operation across various speeds (from 50 mm/s to 1000 mm/s).Q: When can I expect dispatching of sample units after placing an estimate request?

A: Upon submitting an estimate request, qualified suppliers typically dispatch sample units promptly, subject to confirmationensuring minimal delay in your evaluation or procurement process.Q: How does the zero-leakage design improve operational reliability?

A: By eliminating external leakage, the cylinder maintains system pressure efficiently, reduces maintenance requirements, and upholds process cleanliness, essential in automated and sensitive applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Cylinders Category

Fine Lock/Lock-Up Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Wall Thickness : 5 mm 8 mm

Structure : Other, Double acting hydraulic cylinder

Capacity : Customizable as per application

Rod : Chrome plated, highstrength steel

Valve Mounted Guide Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Wall Thickness : 2.5 mm

Structure : Other, Guide cylinder with integrated valve

Capacity : Single/Double acting

Rod : Hard chrome plated steel

3 Position Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Wall Thickness : Heavyduty precision honed barrel

Structure : Other, Compact round barrel design

Capacity : Multiple position actuation (3positions)

Rod : Doubleacting chrome plated steel rod

Dual Rod Cylinder

Price 500-100000 INR / Piece

Minimum Order Quantity : 1 Piece

Wall Thickness : 5 mm

Structure : Other, Tierod construction

Capacity : Variable, dependent on bore size and stroke

Rod : Double rod

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry